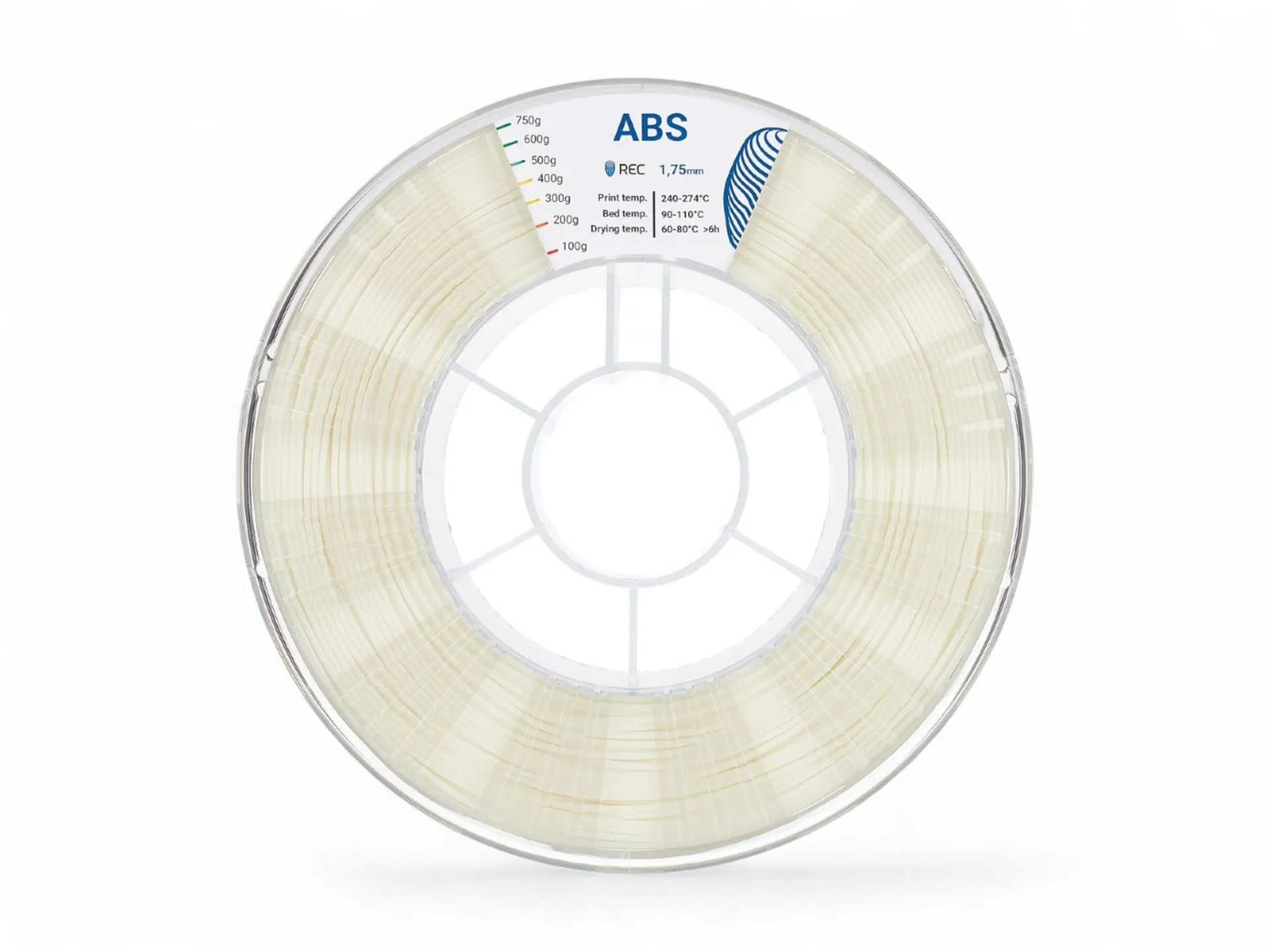

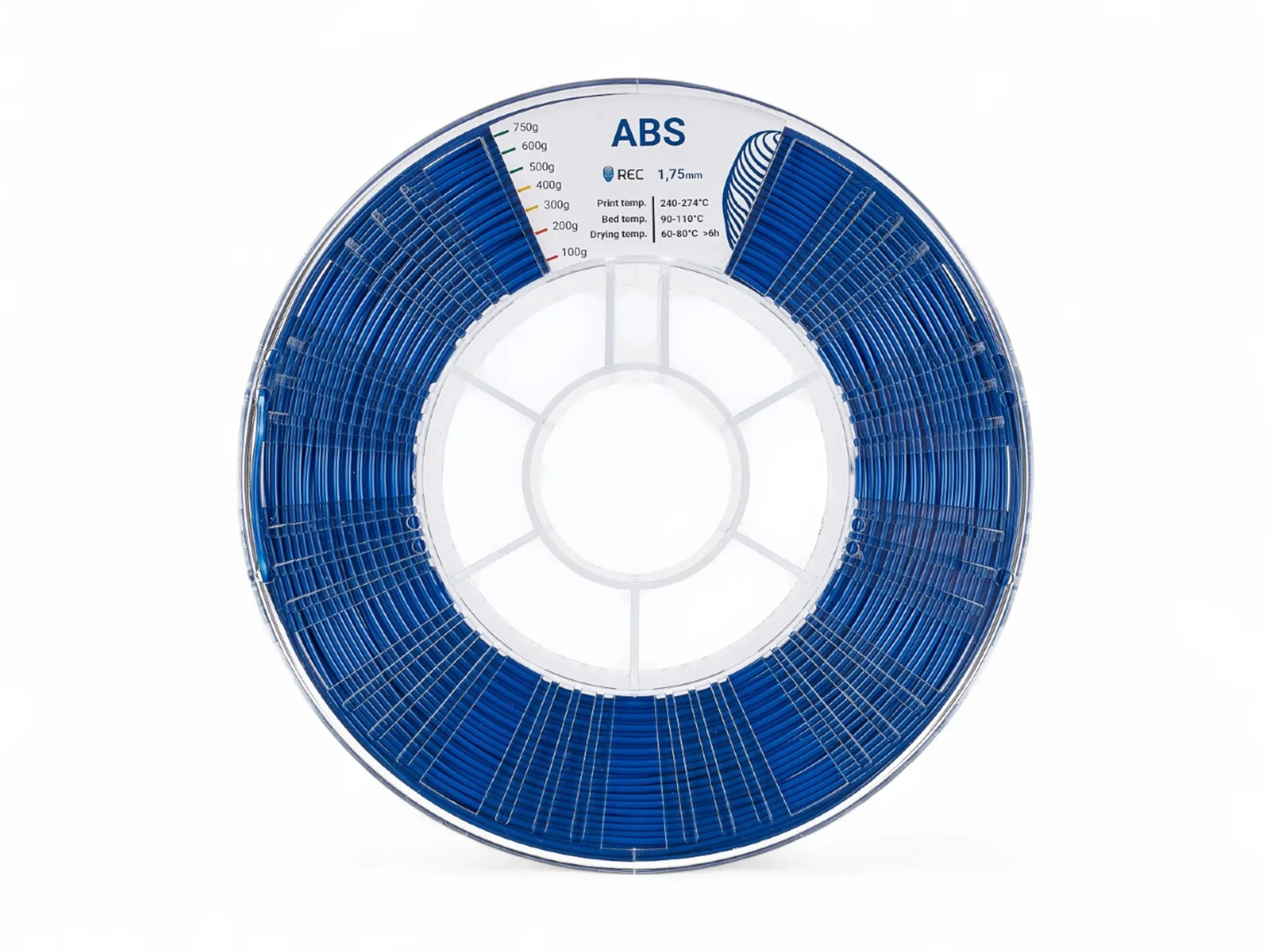

REC ABS is a shock-resistant plastic, most of the plastic objects around us are made of ABS. The material is perfectly suitable for 3D printing of load-bearing objects - gears, mechanisms, housings, hooks, handles, holders, etc., as it provides high strength and durability of models. It is perfectly amenable to mechanical processing and painting.

It is soluble in acetone. For gluing models and as a coating of the 3D printer table, we recommend using a solution of ABS plastic in acetone.

Special properties: when printing at 270°C, the part acquires injection molding characteristics.

Each coil is packed in a reusable vacuum bag with silica gel, so that the plastic does not lose its properties during storage.

It is soluble in acetone. For gluing models and as a coating of the 3D printer table, we recommend using a solution of ABS plastic in acetone.

Special properties: when printing at 270°C, the part acquires injection molding characteristics.

Each coil is packed in a reusable vacuum bag with silica gel, so that the plastic does not lose its properties during storage.

| Print Settings | |

| Nozzle temperature | 240-270°C |

| Table temperature | 90-110°C |

| Blowing | not recommended |

| Min. nozzle diameter | 0.1 mm |

| Safety | ||

| The defined component | Volume of secretions, mg/mC | MPC, mg/mC |

| Methanol | <0,1 | 1 |

| Acetaldehyde | <0,5 | 5 |

| Formaldehyde | 0,197 +/- 0,049 | 5 |

| Styrene | <0,05 | 30 |

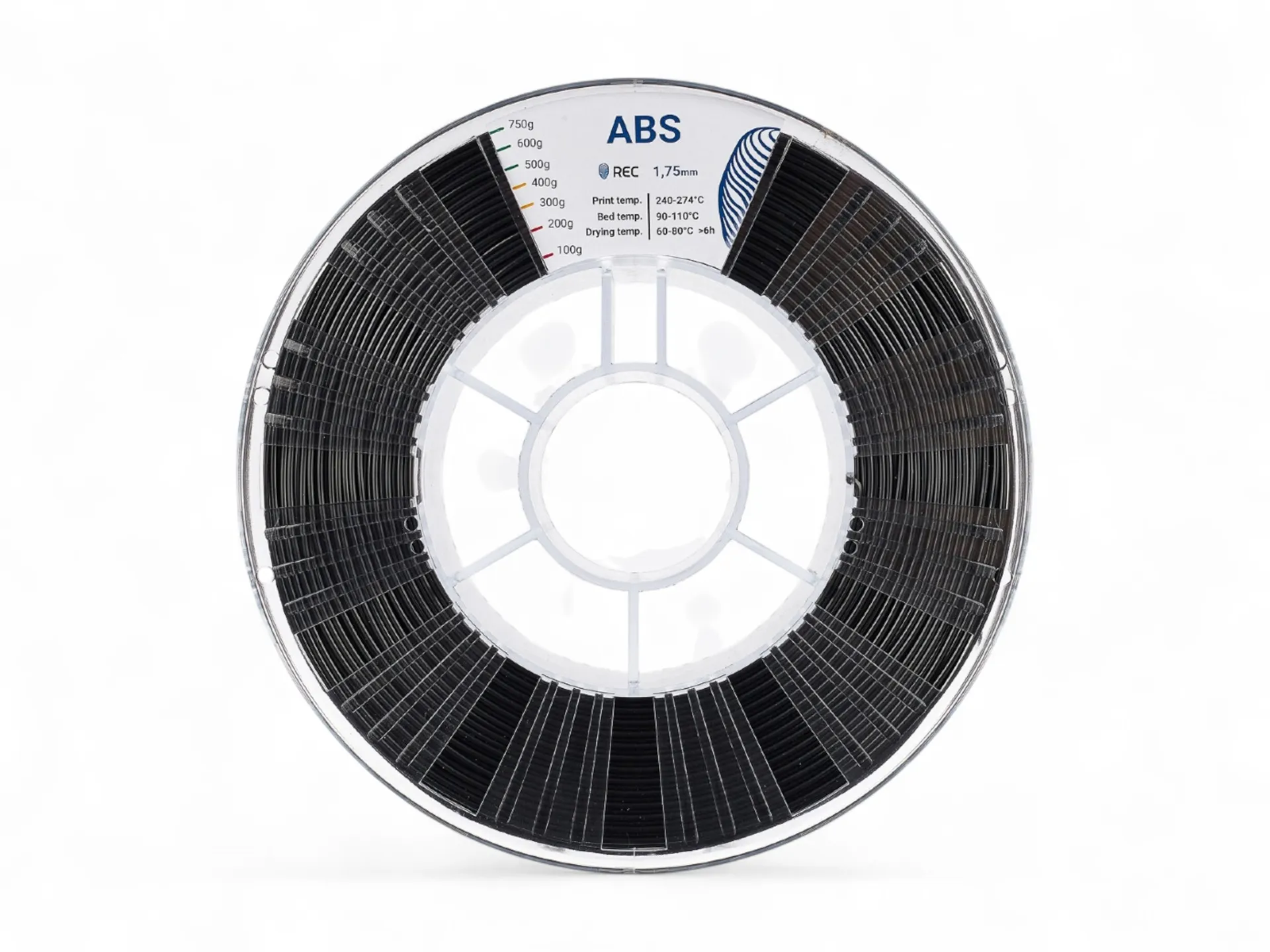

REC ABS is a shock-resistant plastic, most of the plastic objects around us are made of ABS. The material is perfectly suitable for 3D printing of load-bearing objects - gears, mechanisms, housings, hooks, handles, holders, etc., as it provides high strength and durability of models. It is perfectly amenable to mechanical processing and painting.

It is soluble in acetone. For gluing models and as a coating of the 3D printer table, we recommend using a solution of ABS plastic in acetone.

Special properties: when printing at 270°C, the part acquires injection molding characteristics.

Each coil is packed in a reusable vacuum bag with silica gel, so that the plastic does not lose its properties during storage.

It is soluble in acetone. For gluing models and as a coating of the 3D printer table, we recommend using a solution of ABS plastic in acetone.

Special properties: when printing at 270°C, the part acquires injection molding characteristics.

Each coil is packed in a reusable vacuum bag with silica gel, so that the plastic does not lose its properties during storage.

| Print Settings | |

| Nozzle temperature | 240-270°C |

| Table temperature | 90-110°C |

| Blowing | not recommended |

| Min. nozzle diameter | 0.1 mm |

| Safety | ||

| The defined component | Volume of secretions, mg/mC | MPC, mg/mC |

| Methanol | <0,1 | 1 |

| Acetaldehyde | <0,5 | 5 |

| Formaldehyde | 0,197 +/- 0,049 | 5 |

| Styrene | <0,05 | 30 |

- Общие характеристики

Механические характеристикиПлотность 1,05 г/см3 Температура эксплуатации от -40°С до +90°С Температура размягчения ~ 103°С Страна производитель Россия

Электрические характеристикиУдарная вязкость по Шарпи 180,14 кДж/м2 Прочность при растяжении вдоль слоев 29,6 МПа Модуль упругости при растяжении вдоль слоев 1,27 ГПа Прочность на изгиб 65,4 МПа Модуль упругости на изгиб 2,14 ГПа Максимальная нагрузка на изгиб 103 Н Прочность при растяжении поперек слоев 19,7 МПа Модуль упругости при растяжении поперек слоев 2,34 ГПа Максимальная нагрузка на растяжение 785 Н Прочность на сжатие 49,3 МПа Модуль упругости на сжатие 1,71 ГПа Максимальная нагрузка на сжатие 5994 Н Предел текучести при растяжени и при температуре 23°С 52 МПа Прочность при изгибе 2,8 мм/мин. 23°C 70 МПа Твердость по Роквеллу (шкала R) Ударная 112 Вязкость по Изоду 25 кДж/м2 Масло-бензостойкость (максимальное изменение формы за 24 часа) 0.2% Кислородный индекс, %O2 по ГОСТ 21793-76 18.2-18.5 Массовая доля золы по ГОСТ 15973 Менее 0,01%

Транспортные характеристикиУдельное электрическое сопротивление на постоянном токе 1,4х1015 ОМ/см Диэлектрическая проницаемость на постоянном токе 3,15 Диэлектрическая проницаемость на частоте 50 кГц 3,06 Тангенс угла диэлектических потерь на частоте 50 кГц 0,0011 Электрическая прочность 16 кВ/мм Габариты упаковки 315х320х105 мм Вес нетто 2000 грамм Вес брутто 3 кг